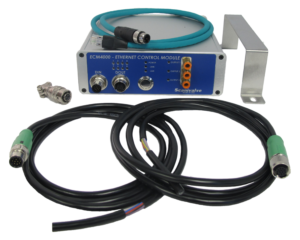

Ethernet Control Module

Features and Specifications

- Ethernet communications

- Dual-Core Processor

- 8 programmable digital inputs

- 8 programmable digital outputs

- 3 Internal pneumatic solenoids

- 8 Status LED’s for digital outputs

- IEEE1588-2008v2 PTP compatible

- Integrated web server

- 19′ Rackmount variation available

Overview

ECM4000 – Ethernet Control Module The ECM4000 was designed to support a wide range of pressure measurement system configurations. It provides a single point of communication for multiple pressure scanners as well as a simple solution for managing control pressures to the scanners. The ECM4000 is built around a core function of creating and executing scripts which can include responding to digital input controls, cycling digital outputs, cycling control pressures, sending Ethernet commands, querying pressure scanners or inserting timed delays. These basic functions can be programmed to help support a variety of needs in a pressure measurement system.

Applications

The ECM4000’s flexible design allows it to be used for a wide variety of applications. It can be used as the ‘center’ of any Scanivalve pressure measurement system. It provides an easy interface to manage the data collection of multiple pressure scanners, automatically orchestrate control pressures to the scanners and provide additional digital inputs and outputs to interface and manage a wide variety of inputs and outputs. The IEEE1588v2 support gives the user the option to provide accurate time-stamping for externally sourced hardware triggers or to use the ECM4000 itself as a external trigger source to the pressure scanners, all synchronized to an IEEE1588 “grandmaster”. A heater can be integrated into the ECM4000 to allow sub-zero temperature operation, which allows the ECM4000 to be mounted in remote areas during flight test at altitude.

The flexibility provided by the ECM4000 makes it an excellent fit in many applications such as:

- Compression stage research and testing

- Automation and control systems

- Steam turbine purge and control systems

- Wind turbine blade control systems

- Automotive aerodynamic studies (wind tunnel or on-car)

- Wind and building engineering

- Flight performance and testing

- Educational and research facilities

- And many more

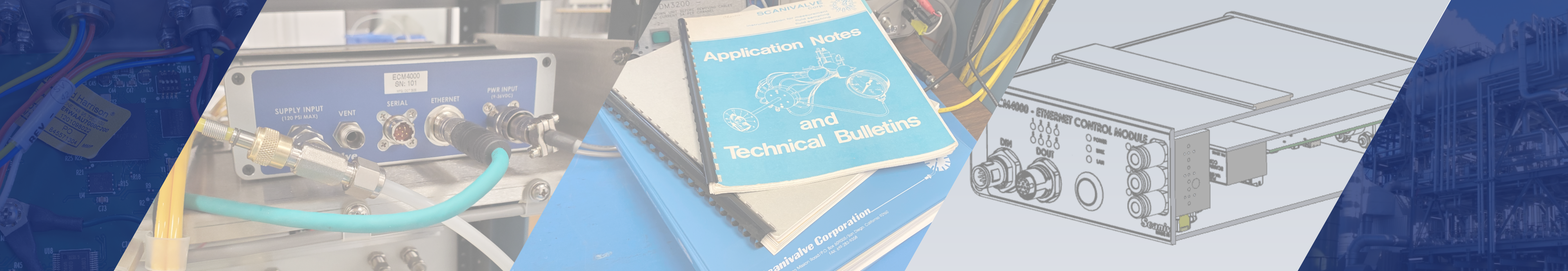

Documentation

-

- ECM4000 Hardware & Software Manual

(3 MB)

(3 MB) - ECM4000 Data Sheet

(1 MB)

(1 MB) - ECM4000 Sales Drawing

(136 KB)

(136 KB) - ECM4000 Rackmount Sales Drawing

(76 KB)

(76 KB) - ECM4000-MPS4264 System Architecture Example

(312 KB)

(312 KB)

- ECM4000 Hardware & Software Manual

3D Models

- ECM4000

(12 MB)

(12 MB) - ECM4000 Rackmount

(13 MB)

(13 MB)