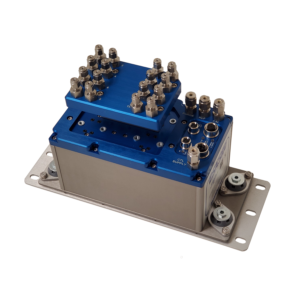

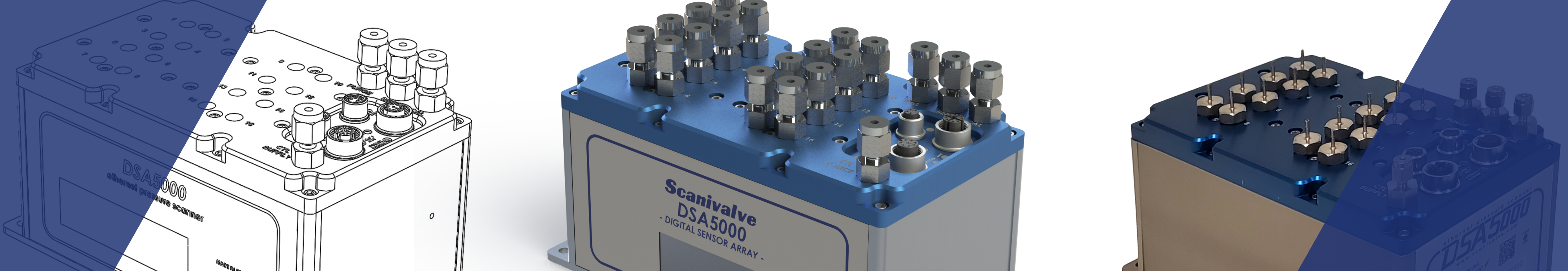

Intelligent, Versatile 16-Channel Ethernet Pressure Scanner

Features and Specifications

- Engineering Unit Data Stream up to 5,000Hz (Samples/Channel/Second)

- Accuracies as low as ±0.04% Full Scale

- 4″H2O to 1,500psi Pressure Ranges

- Non-Multiplexed, Synchronous Scanning

- IEEE1588-2008v2 PTP Compliant

- 1Gb Ethernet Connection

- 24-bit A/D Converters

- Multi-Drop Architecture for Multiple Module Simplicity

- Integrated Web Server

- Customizable Builds:

- Gas or All-Media Measurement

- TCP/IP (Native) or iDDS Communications

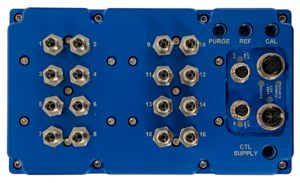

- “QD” (Quick Disconnect) Input Header Option

- Integrated Heater

- Shock Mount

- Multiple Pneumatic Fitting Options

Overview

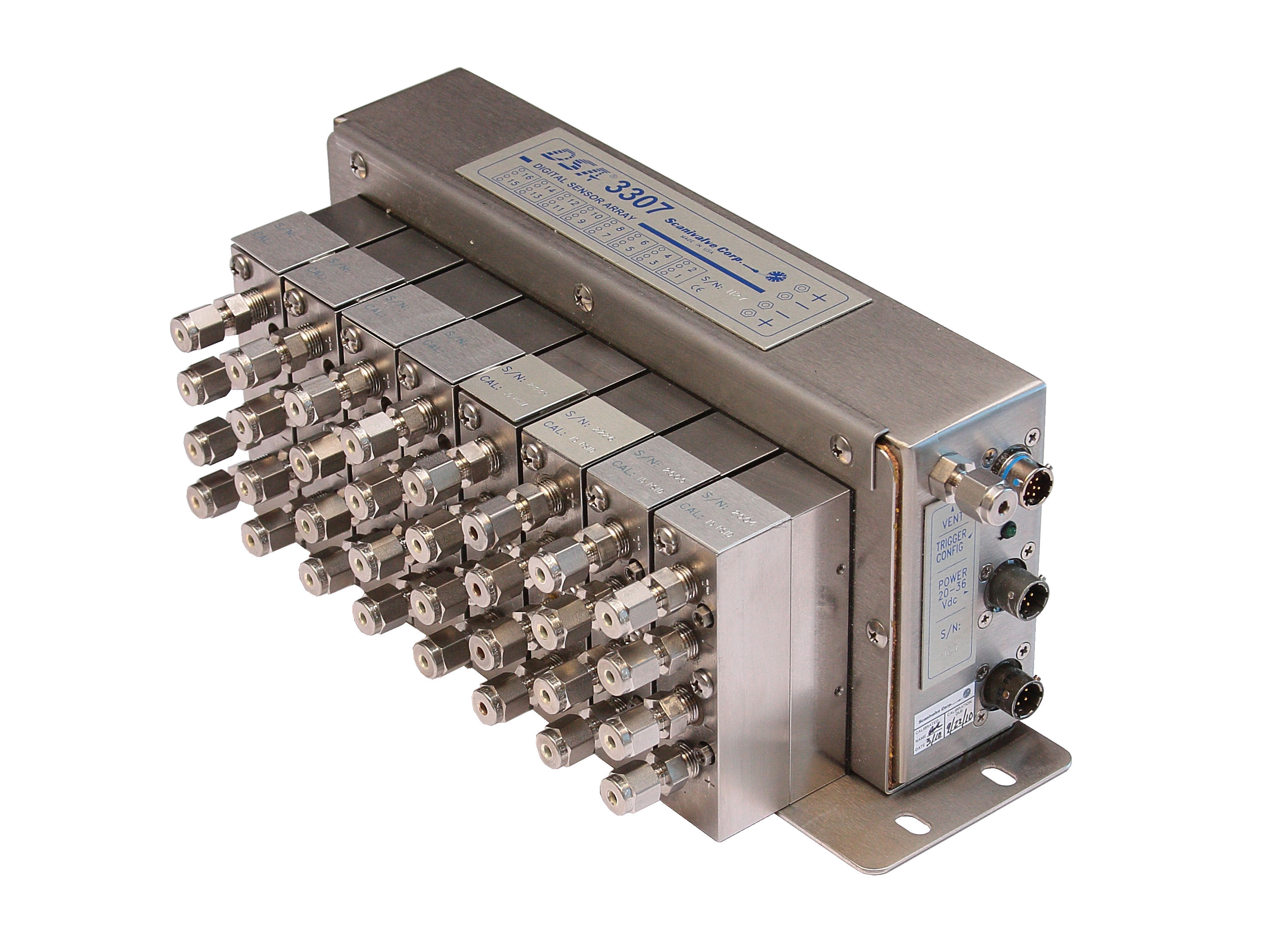

The DSA5000 pressure scanner is a versatile, all-in-one data acquisition system. Each DSA5000 uses a pressure sensor per channel architecture. All data acquisition, data conversion, and communications are handled by the integrated process and A/D converters. Unlike any other pressure scanner available, the DSA5000 utilizes an individual A/D converter for each sensor allowing fully synchronous data collection. Together, these features provide easy setup, simple operation, and long term reliability.

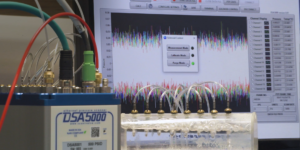

The DSA5000 is designed to output an engineering unit data stream over an Ethernet connection. A broad selection of data output formats and options are available including; TCP/IP, UDP and FTP data transfer protocols, ASCII and Binary formats, and iDDS. A Webserver is fully integrated providing an intuitive and easy means for configuration and operation. Scanivalve has also developed and engineered a new and unique form of connectivity called Scanivalve Synchronous Ethernet Protocol, or SSEP. This proprietary feature allows for a single DSA5000 ‘controller’ to be used to control and collect data from a number of other DSA5000 modules connected to an isolated, mini-network. Module identification, configuration, and synchronization happens seamlessly, minimizing setup time and frustration, and all communication for the SSEP network is performed through the single ‘controller’ module.

Several builds are available to support numerous types of pressure measurement applications. The standard gas builds are use for dry air measurements. The All-Media builds can be used for any compatible media, including oil, fuel, water or vapor. Standard builds use the native Scanivalve TCP/IP communications, where iDDS builds can be configured for iDDS systems.

The result of the DSA5000’s careful design is a complete package that makes multi-point pressure acquisition tasks simple. The DSA5000’s functionality and flexibility make it an excellent fit for a wide range of applications.

Applications

The DSA5000 is a versatile scanner, designed for a wide range of applications. The rugged package, customizable pneumatic interface options, and configurability make it an ideal fit in applications such as gas turbine testing, flight testing, industrial, wind engineering, and others. The user-friendly interface, simple operation, and low overhead requirements also make it ideal for educational facilities, small research and development projects, automotive testing, and other quick tests with low channel counts. The DSA5000 supports a wide range of pressure inputs, extending beyond the capabilities of previous pressure scanner capabilities. The DAS5000 is also IP67 rated, can be configured with internal heating, has the option for a “Quick-Disconnect” input header, has user-changeable input fittings, and can use an optional bolt-on shock mount, which help the DSA5000 meet the most extreme and demanding testing requirements.

The DSA5000 can be used in applications such as:

- Compression stage research and testing

- Boundary layer measurements

- Steam turbine efficiency and performance

- Wind turbine blade monitor and control systems

- Automotive aerodynamic studies (wind tunnel or on-car)

- Wind and building engineering

- Flight performance and testing

- Educational and research facilities

- And many more

Documentation

-

- DSA5000 Data Sheet

(0.8 MB)

(0.8 MB) - DSA5000 Hardware & Software Manual

(4 MB)

(4 MB) - DSA5000 QuickStart Guide

(0.5 MB)

(0.5 MB) - DSA5000 Replacing a DSA3200 (Emulator)

(0.5 MB)

(0.5 MB)

- DSA5000 Data Sheet

3D Models

-

- DSA5000 Standard

(7.1 MB)

(7.1 MB) - DSA5000 w/QD Input Header

(5.8 MB)

(5.8 MB) - DSA5000 w/Shock Mount Kit

(6.8 MB)

(6.8 MB) - DSA5000 w/QD Header and Shock Mount

(6.8 MB)

(6.8 MB)

- DSA5000 Standard