Scanivalve leads the world in intelligent pressure and temperature measurement instrumentation. We have achieved this by providing each customer with attention, innovation, and quality equipment to solve their specific needs. Our worldwide team is waiting to help you, too. Find out all about us here.

MAIN LOCATION

Scanivalve Corporation

1722 North Madson St

Liberty Lake, Washington, 99019

We can be reached at:

Main Phone: 1 (509) 891-9970

Toll Free: 1 (800) 935-5151

Fax: 1 (509) 891-9481

Email: scanco@scanivalve.com

For those who are visiting Scanivalve, we have corporate rates at both the Quality Inn Valley Suites Hotel and the Oxford Suites Hotel. These Hotels are centrally located with many restaurants nearby. A free breakfast is included in the rate, plus the use of exercise/fitness facilities

Spokane Airport to Scanivalve

Approximate Distance: 21.2 miles

Approximate Travel Time: 26 minutes

Driving directions:

Exit the airport east on W. Airport Dr. by turning right (0.2 miles)

Take the US-2 East ramp (0.3 miles)

Merge onto US-2 East (0.9 miles)

Take the I-90 East exit (0.5 miles)

Merge onto I-90 East/US-395 North (2.9 miles)

Merge onto I-90 East to the Liberty Lake/Otis Orchards exit #296 (16 miles)

Go straight through the stoplight and turn right on N. Madson Street (North Madson Street is the 3rd stoplight) (0.4 miles)

Spokane Airport – Quality Inn Valley Suites Hotel – Scanivalve

Quality Inn Valley Suites Hotel:

Address: E. 8923 Mission Ave

Tel: 509-928-5218

Fax: 509-928-5211

Directions from Spokane Airport to Quality Inn Valley Suites

Approximate Distance: 12 miles

Approximate Travel Time: 14 minutes

Exit the airport eastbound on W. Airport Dr. by turning right (0.2 miles)

Take the US-2 East ramp (0.3 miles)

Merge onto US-2 East (0.9 miles)

Take the I-90 East exit (0.5 miles)

Merge onto I-90 E/US-2 E/US-395 N (2.9 miles)

Stay on I-90 East to the Argonne Rd exit #287 (7 miles)

Turn right (south) on Argonne Rd to Mission Ave (0.1 miles)

Turn right on Mission Ave (Hotel is on right side) (0.1 miles)

From Quality Inn Valley Suites Hotel to Scanivalve Headquarters:

Distance: 10.2 miles

Approximate travel time: 12 minutes

From the hotel parking lot

Turn left, heading East on East Mission Ave (0.1 miles)

Turn left at stoplight on N. Mullan Rd (0.1 miles)

Merge onto I-90 East to the Liberty Lake/Otis Orchards exit #296 (9 miles)

Go straight through the stoplight

Turn right on N. Madson Street (0.4 miles) (N. Madson Street is the 3rd stoplight)

Turn left into Scanivalve parking lot (0.2 miles)

Scanivalve Airport – Oxford Suites Hotel – Scanivalve

Oxford Suites Hotel:

Address: 15015 E. Indiana Ave

Tel: 509-847-1000

From Spokane Airport to Oxford Suites Hotel:

Distance: 16 miles

Approximate travel time: 16 minutes

Exit the airport eastbound on W. Airport Dr by turning right (0.2 miles)

Take the US-2 East ramp (0.3 miles)

Merge onto US-2 East (0.9 miles)

Take the I-90 East exit (0.5 miles)

Merge onto I-90 E/US-2 E/US-395 N (2.9 miles)

Stay on I-90 East to the N. Sullivan Road Exit #291

Turn left on N. Sullivan Road

Turn left on E. Indiana Ave (Hotel is on the right side)

From Oxford Suites Hotel to Scanivalve Headquarters:

Distance: 6.1miles

Approximate travel time: 10 minutes

From the hotel parking lot turn left on E. Indiana Ave

Turn right on N. Sullivan Rd (0.2 miles)

Merge onto I-90 East to the Liberty Lake/Otis Orchards exit #296 (7 miles)

Go straight through the stoplight

Turn right on N. Madson Street (0.4 miles) (N. Madson Street is the 3rd stoplight)

Turn left into Scanivalve parking lot (0.2 miles)

It all began with our founder, JC Pemberton, working at the Boeing wind tunnel in Seattle, Washington. His development of a mechanical scanning valve that multiplexed many pressure signals into one transducer revolutionized the data acquisition of pressure measurement. At the same time, electrical strain gauge transducers were being introduced. Shortly after the initial mechanical “Scanivalve,” JC left Boeing and founded Scanivalve Corporation in 1955. News of the mechanical “Scanivalve” spread quickly throughout the wind tunnel industry, finding it’s way into the ears of other industries. Soon, these mechanical pressure measurement devices were being used in gas turbine and process control industry, expanding and establishing the Scanivalve name and reputation.

In the following years, besides pressure scanners, Scanivalve developed a comprehensive product line of more than 3000 items for facilitating easy pressure & pneumatic connections. These include small diameter plastic tubing and steel tubulations (.031 inch to .125 inch), as well as a wide selection of pneumatic manifolds and connectors.

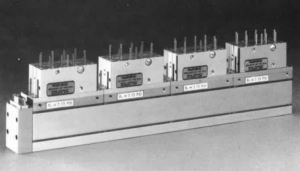

In the 1970’s, Scanivalve developed the combination of calibration valving applied to individual miniature silicon sensors. The concept allowed computer correction of temperature errors inherent in these small silicon pressure sensors. Measurements of the individual sensors were now multiplexed electronically rather than mechanically, thus allowing faster sampling rates. They became known as ZOC pressure scanners (Zero, Operate & Calibrate).

In 1982 JC Pemberton sold the company to his sons, Addison and Jim. Shortly afterwards, the PC came onto the industrial scene. Scanivalve developed the Hyscan2000 pressure measurement system to stay in the forefront of technology. The Hyscan2000 was a PC-based pressure data acquisition system capable of sampling pressures up to 100,000 channels per second.

Scanivalve’s innovative engineering and sales team looked forward and saw Ethernet becoming one of the dominant communication busses for physical measurement. In 1995, Scanivalve relocated to a brand new manufacturing/headquarters facility located in Liberty Lake (Spokane), Washington. That same year we introduced our first Ethernet TCP/IP intelligent 16 channel pressure measurement system. The model DSA3000 series incorporated not only 16 pressure sensors but also an A/D, microprocessor, and auto calibration valving to allow for EU data output.

The model DTS3250 Digital Thermocouple Scanner was a natural spinoff with our technology. With this model, introduced in 2001, a user could measure both pressure and temperature quickly, accurately, and on the same LAN.

As the pace of technology has quickened, Scanivalve has kept pace. In 2002, a miniature pressure measurement system that is low cost and easy to use was introduced. It communicated USB and was called the RAD3200 Remote A/D. As the decade continued this product was upgraded in 2009 into the ERAD4000 Remote A/D with an Ethernet 100baseT network connection, thus eliminating the USB cable.

These successive new intelligent products have established Scanivalve as a highly innovative company solving industry problems, and leading to the addition of products such as the MPS4000 series, DSM series, and many more. Scanivalve continues with strong innovation and engineering to continue to improve the world of multi-channel measurement instrumentation. They have helped broaden the industry applications for Scanivalve beyond just aerospace to include the power industry, all turbomachinery testing, factory automation, and process control.

Scanivalve’s quality commitment extends from management to the shop floor. Our design and manufacturing teams are dedicated to producing the best solutions for your specific needs. As part of our effort, Scanivalve Corporation is certified to ISO 9001:2015 and conforms to quality standard ANSI Z540.1. Scanivalve equipment meets the EC European Community standards for EMI, EMS, and ESD (EC1000-4-2, EC1000-4-3, EC1000-4-5)

Scanivalve’s mission is to be the world leader in the manufacture of physical measurement equipment. We shall continue to provide innovative, state-of-the-art measurement solutions to our customers. Our goal is total customer satisfaction and confidence in our goods and services.

Quality Policy

Scanivalve is committed to meeting customer requirements and enhancing customer satisfaction through continual improvement of its products, services, and the quality management system.

Scanivalve has distributors in many countries throughout the world. Please feel free to contact the distributor for your country. If there is no distributor listed for your country please contact Scanivalve US headquarters for any assistance.

Click here to view our complete list of distributors!

Below is a list of partners that provide interfaces with Scanivalve’s products, and have the capabilities to customize drivers for our products.

Partner Links

- Acra Control

Acra Control is a premier supplier of high-performance data acquisition systems to the world’s aerospace and transportation industries. They provide innovative, cost-effective and durable solutions for their most stringent measurement needs. Their products are in use in over 40 countries worldwide in the most demanding applications and harshest of environments”. Their card number KAD/MDC/002 and KAM/MDC/002 interfaces Scanivalve’s ZOC33 64 channel pressure scanners. - Aeroprobe

Aeroprobe is a manufacturer of multi-point air probes. They have developed interfaces to Scanivalve’s ZOC, MPS, and DSA pressure scanners, as well as our ERAD4000 and DSM4000 pressure data systems. They can tune the pneumatics between the air probes and Scanivalve products. - Aiolos Engineering

Aiolos designs and constructs test facilities, such as wind tunnels and chambers, for aerospace, automotive and academic clients. Aiolos provides custom integration with our products, such as DSA3200 pressure scanners, RAD4000 pressure measurement systems, and MPS4200 series scanners into the overall facility data acquisition and control systems. - Apex Turbine Testing Technologies

Apex Turbine Testing Technologies is a supplier of test and analysis solutions, delivering fully integrated data acquisition systems with analysis software world-wide for aircraft propulsion systems and gas turbines for power generation. Apex has integrated MPS4200 series and DSA5000 series scanners into their DX+ software package. Contact Apex for more information on Scanivalve device support. - Cal-Bay Systems

Cal-Bay Systems, a National Instruments Select Integrator, specializes in developing turnkey systems for testing, measurement and automation. Cal-Bay developed LabVIEW drivers and offers expertise for our DSA3200 series pressure scanners, DTS3250 thermocouple scanners, and DSA3016 rack mounted pressure scanners. - Safran Test Cells (formerly Cenco, Inc.)

Safran, formerly Cenco, is an integrator and builder of gas turbine test cells. Safran’s software interfaces with our DSA3200 series Pressure Scanners, DTS3250/4050 Thermocouple Scanners, and DSA5000 pressure scanners. - Complete Networks Incorporated

Complete Networks specializes in automated test and data acquisition software. The company developed LabVIEW Drivers for our DSA3200 series pressure scanners, DTS3250 thermocouple scanners, DSM3200/ZOC pressure measurement systems and DSA3016 rack mounted pressure scanners. - Dewetron / Dewesoft

Dewetron PC instruments are versatile data acquisition systems which record synchronously from analog and digital sensors, GPS and IRIG interfaces, the automotive CAN-BUS, and video cameras. Versatile DEWESoft acquisition software allows a wide variety of sensors to be connected via Ethernet, RS232, USB, Firewire, and more. The Scanivalve DSA3217-PTP digital pressure sensor array, MPS4264 miniature pressure scanner, and DSA5000 scanner has been integrated into the Dewesoft software. The Scanivalve software plugin is available upon request for any licensed copy of Dewesoft. Additional informaiton on Scanivalve integration can be found using this link (click here). - Jacobs Technology

Jacobs Technology designs, builds, operates and maintains aerospace and automotive facilities for both test and manufacturing sites. Jacobs Technology’s Testslate acquisition software interfaces with our DSA Pressure Scanners and DTS Temperature scanners. - Kratos Defense–(Herley Lancaster)

Herley Lancaster is now a division of the Kratos Corporation and focuses its efforts on the design and manufacture of flight instrumentation systems for manned aircraft, missile systems, and unmanned aerial vehicles (UAVs).Their card number 770-0410, interfaces up to 4 each Scanivalve ZOC33 pressure scanners (256 pressure channels). - Kepware Technologies

Kepware Technologies developed an OPC server for our DSA3200 series pressure scanners and DTS3250 thermocouple scanners (16 channel only). The OPC server drivers also support the DSA-PTP series and DTS4050 series (16 channel only). - KineticaRT

KineticaRT provides supervisory control and data acquisition software for motor sport, automotive, and aerospace wind tunnels. The company developed an OPC server for our RAD3200/4000 and DSM3400 pressure measurement systems. - MDS Aero Systems

MDS designs and builds highly complex multi-million-dollar gas turbine engine test facilities all over the world. MDS has worked to incorporate the DTS4050 and DSA5000 into their systems and facilities. Scanivalve worked directly with MDS to integrate the DSA5000 iDDS modules into the nxDAS system. - ReACT Technologies Inc.

ReACT Technologies provides real-time computer systems integration for R&D applications, including wind tunnel testing. ReACT interfaces with our DSA3200 series Pressure Scanners, RAD3200/4000 and DSM3400 pressure measurement systems. - Teletronics Technology Corporation

Teletronics Technology Corporation provides data acquisition and instrumentation products and engineering services to both small and major clients. Their primary business area is data acquisition and instrumentation used in modern high-performance aircraft, missiles, aerospace vehicles, underwater vehicles and land vehicles. They have developed an Ethernet interface card EUP-105-4 to Scanivalve’s Intelligent pressure & thermocouple scanners, models DSA3200, DSA3016 & DTS3250.

Scanivalve Corporation employs an innovative and experienced staff of engineers and technicians responsible for the development, production, and support of all Scanivalve products. Our sales and application engineers are ready and eager to come up with practical solutions for your pressure and temperature measurement applications. Besides possessing strong Scanivalve product knowledge, they have decades of industry application experience.

Our production and quality team manufactures our products to the highest standards, using state-of-the-art manufacturing techniques and equipment. Since we manufacture our equipment in our own factory, our production team is ideally situated to turn our designs for you into practical reality.