Features and Specifications

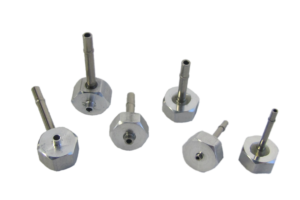

Pressure Tap

Straight or 90 degree configuration with .040″ or .063″ tubulation

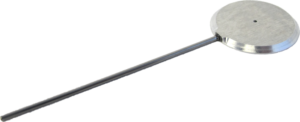

Pressure Patch

A 1.85″ non-bulged .040″ tubulation fixed to a thin, aluminum body with a single port hole

Overview and Application

Pressure Taps and Patches provide users with a mountable port on a test article or model, to provide a single measurement port to a single channel of a pressure scanning module. These taps and patches can be fixed to a test article or model according to the application’s needs. Both the tap and patch use a stainless steel tubulation, extruded from an aluminum body.The pressure tap was designed to provide a through-hole option for a measurement port. The “Stickout” length comes in various sizes to accommodate for different material thickness of the test article. Drilling a hole that is the appropriate size of the “Sitckout” will allow the tube to be flush or nearly flush with the surface of the test article. It can be fixed to the test article using the appropriate adhesive on the base of the tap and allowing for the recommended dry time (based on the adhesive). Once dry, the “Stickout” can be shaved to create a flush surface, and will leave you with a bulged tabulation on the underside of the model. Please see the Pressure Tap Sales Drawing for more information.

The pressure patch provides an alternate solution to the pressure tap where drilling holes in the test articles is unacceptable or inconvenient . A stainless steel tube is extruded from the chamber of a small, aluminum body (the disk). This aluminum body can be fixed to the test article using the appropriate adhesive for the application. The design of the path was tested to have minimal aerodynamic influences when fixed to the flat surface of a test article.

Downloads

-

-

- Pressure Tap & Patch

(531 KB)

(531 KB) - Pressure Tap Sales Drawing

(115 KB)

(115 KB) - Scanivalve Accessory Catalog

(8 MB)

(8 MB)

- Pressure Tap & Patch

-